When you become the owner of a sewing machine, you often sit down and read through the user manual, to familiarize yourself with which stitch to use for which fabrics and how to clean it, thread it and all the other general aspects of running a machine. What you don’t always do however is familiarize yourself with which sewing machine needle to use.

Choosing the correct type of needle for the right sewing project is just a task of matching the type of needle to the type and weight of fabric and understanding that needle types relate to the structure of the fabric they are used on.

The size of the needle depends on the size of the fabric yarn, for example, if you’re using a fine fabric then you need a fine needle that will not mar the fabric, but that still has a larger enough eye to ensure that the thread will not fray or break whilst being sewn with.

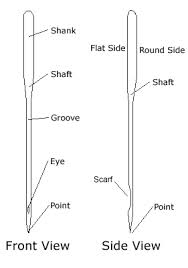

Shank

The Shank is the long part of the needle. The diameter of the shank affects how thick of a hole it makes in the fabric and how big the eye of the needle can be, and thus how thick the thread can be. Ideally, the eye of the needle is just big enough for the thread. Too much extra room in the eye causes extra wear and tear on the thread. Thicker threads and thicker fabrics, obviously, require thicker needles. Besides diameter, flexibility is another important factor. More rigid fabrics, like denim, need more rigid needles.

Needle point

Before synthetic knits were invented, machine needles were sharp. Sharp needles snag or run knit fabric, so more rounded, or ‘Ballpoint’ needles were invented. ‘Universal’ needles are a compromise between ‘Sharps’ and ‘Ballpoint’ needles and can be used on a wider array of fabrics. However, it is best to choose the best needle for each individual project. Ideally, you should choose a new needle each time you start a new project.

- Sharp points (regular) are for use with woven fabrics (including cotton and linen etc) because they cause a minimum amount of puckering and produce an even stitch without damaging the fabric. These are not recommended for use with knits as they can cause skipped stitches. Sharp points are more slender through the shaft and should be used when edge stitching on woven fabrics, sewing on finely woven fabrics or heirloom stitching on very fine fabrics. They are also a good choice when sewing with synthetic suede. These needles come in varying sizes from the finest size 9 to the heaviest size 18.

- Universal Point needles have a slightly rounded point that is similar to the ball point needle and is used for general, everyday sewing of most woven or knit fabrics. The needle is tapered so that it slips through the fabric weave of the knit easily whilst still retaining enough sharpness to pierce the cloth. It is usually Universal needles that come with your sewing machine. They come in many different sizes with the 14/90 and the 11/75 being the most popular.

- Ball Point needles are specifically designed to be used with knit and stretch fabrics. They have a rounded point rather than a sharp one (the larger the size of the needle, the more rounded the needle point) and they push between the fabric yarns rather than piercing them the way the Sharp Points do. The needles should be used when sewing with interlock knits, coarse knits and other fabrics that will run if snagged. The needles come in varying sizes from 9 to 16. The larger the size of the needle, the more rounded the needle point is.

Sizing

For home sewing, size #11 is generally fine for normal weight fabrics. Sizes #11, 14, and 16 are common sizes for home needles, and are based on the old Singer sizing standard. However, there are several types of sizing systems. The same needle may have 4 ‘different’ sizes written on it, which can be very confusing if you are trying to figure out what all those numbers mean.

Often, you will see the sizes separated by a slash, such as 11/75 or 75/11. Here, the ’75’ refers to the “Number Metric” system indicating the diameter of the slimmest part needle blade in the hundredths of a millimeter; that is size, a size ’75’ needle has a diameter of 0.75mm.

Another way to measure needles is the 130/705 H system. This is an international system; the H stands for Hohlkehle in German, which means ‘with scarf’. Scarf refers to the indentation above the eye of the needle. Household needles have a flattened shank so the needle’s eye will be perfectly positioned in relation to the bobbin hook.

Understanding the type of needle as well as the right size is extremely important to achieve a high quality finished project.

The general rule is that the needle size is judged by the type of fabric being sewn, although there are always exceptions:

- Delicate Fabrics: When sewing with fabrics such as silk, chiffon, voile, fine lace or organza a fine “size 9″ needle would usually be the best choice.

- Lightweight Fabrics: When using lighter weight fabrics such as synthetic sheers, batiste, taffeta or velvet would a “size 11″ needle would be the normal choice.

- Medium Weight Fabrics: When sewing with slightly heavier weight fabrics such as gingham, poplin, linen, muslin, chambray, wool crepe, flannel, knits, jersey, wool, wool suiting, or stretch fabrics a “size 14″ needle is generally best.

- Medium-Heavy Fabrics: Sewing with fabrics such as gabardine, heavy suiting or tweed would require a “size 16″ needle.

- Heavy Fabrics: When using heavy weight fabrics such as denim, ticking, upholstery or canvas a “size 18″ needle is the most suitable.

Wear and tear

Imagine how many times a needle passes through the fabric as you sew. A lot!! Often, if you machine is skipping stitches, your thread is breaking, or your fabric is snagging, you may have a damaged needle that looks fine to the naked eye. That tiny tip of the needle wears out, bends, get damaged, etc. The eye of the needle may also develop tiny snags.

As we all know, there may be other problems with the machine, but starting with replacing the needle (with the proper one for the project at hand, of course) is a good place to start. Make it a habit to change your needle.